Crankshaft grinding machine

You have come to the right place if you are looking for a new crankshaft grinding machine. We manufacture your machine tailor-made for your individual requirements! We look forward to your inquiry!

Your benefits

As a manufacturer of industrial grinding machines for metal, GST Grinder delivers highest precision solutions since 1992.

- Specialized in circular grinding ✓

- Completely individual ✓

- High-precision technology ✓

- Short retooling times ✓

- Integrated automation ✓

- Improved energy balance ✓

Tailor-made solutions

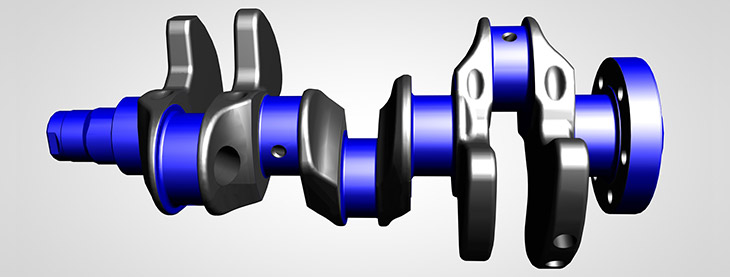

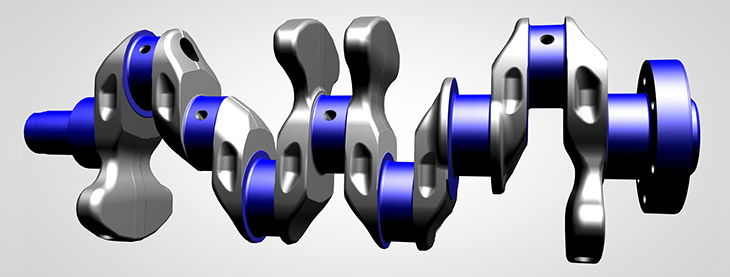

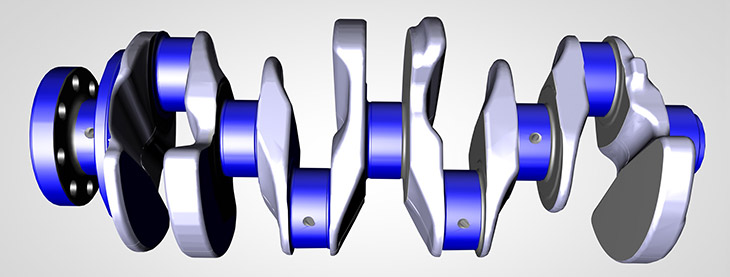

The crankshaft is an essential part of the internal combustion engine. When it comes to processing large quantities with highest accuracy, GST is a flexible provider for your requirements. Since the highest level of precision is required for this type of grinding, GST has developed various concepts. Depending on our customers’ requirements, each machine is specially planned, designed and manufactured in Austria according to highest quality standards.

Grinding main bearings, pin bearings, flanges, journals, flat surfaces & polygons

Examples of successfully realized projects:

Double Jet CBN - Double-spindle angular infeed grinder

1,200 parts/day in 3-shift operation

Applications:

- Flange, journal and encoder wheel seat

- Flange, journal and bore

- Flange, journal and balance shaft seat

- Grinding with CBN wheels in a single clamping set-up

- Grinding wheel max. Ø 600mm

Double Jet Orbital - Double spindle orbital grinder

500 parts/day in 3-shift operation

Applications:

- Rough and finish grinding of main and pin bearings

- Grinding with CBN wheels in a single clamping set-up

- Grinding wheel max. Ø 600mm

Single Jet Profile CBN - Single-spindle straight or angular infeed grinder

1,200 parts/day in 3-shift operation

Applications:

- Flanges, journal and encoder wheel seat, balance shaft seats, and encoder wheel seats of crankshafts

- Grinding with CBN wheel

- Grinding wheel max. Ø 600mm

Double Jet C/2 - Double-spindle straight infeed grinder

1,000 parts/day in 3-shift operation

Applications:

- Flange and journal

- Flange, journal and encoder wheel seat

- Flange and journal and balance shaft seat

- Grinding with corundum wheels in a single clamping set-up

- Grinding wheel max. Ø 900mm

Multi-Wheel C - Single-spindle multi-wheel grinder

1,200 parts/day in 3-shift operation

Applications:

- Flange-mounted wheel sets

- All main bearings on crankshaft and camshaft

- Grinding with corundum wheels in a single clamping set-up

- Grinding wheel max. Ø 750mm

- Grinding wheel width max. 500mm

Single Jet C

1,200 parts/day in 3-shift operation

Applications:

- Machining of crankshafts

- Diameters and plane surfaces by straight and angular infeed grinding in a single clamping set-up

- Complete grinding of the shaft in a single clamping set-up with corundum grinding wheels

Feel free to contact us without any obligations!

Your contact person

Markus Aschauer, Dipl.W.Ing.(FH)

Technical Sales

GST Grinder GmbH

Your grinding machine manufacturer in Austria!

Contact me:

Phone: +43 (0) 2267 3250-24

Mobile: +43 (0) 650 3250 005

E-Mail: markus.aschauer@gst.at