Accessories made for you

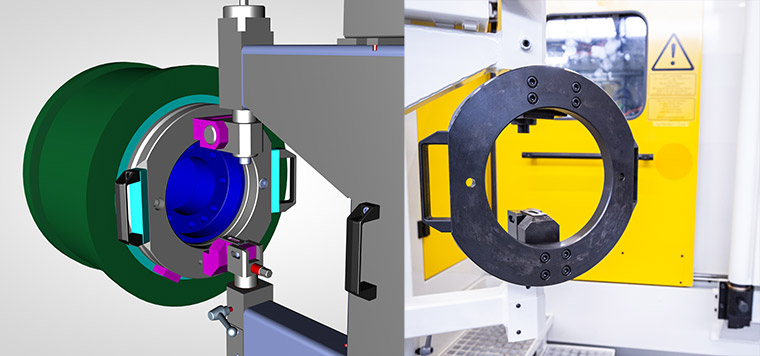

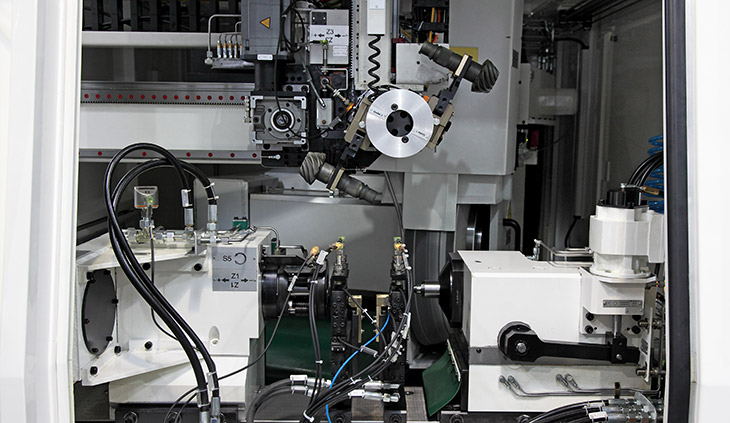

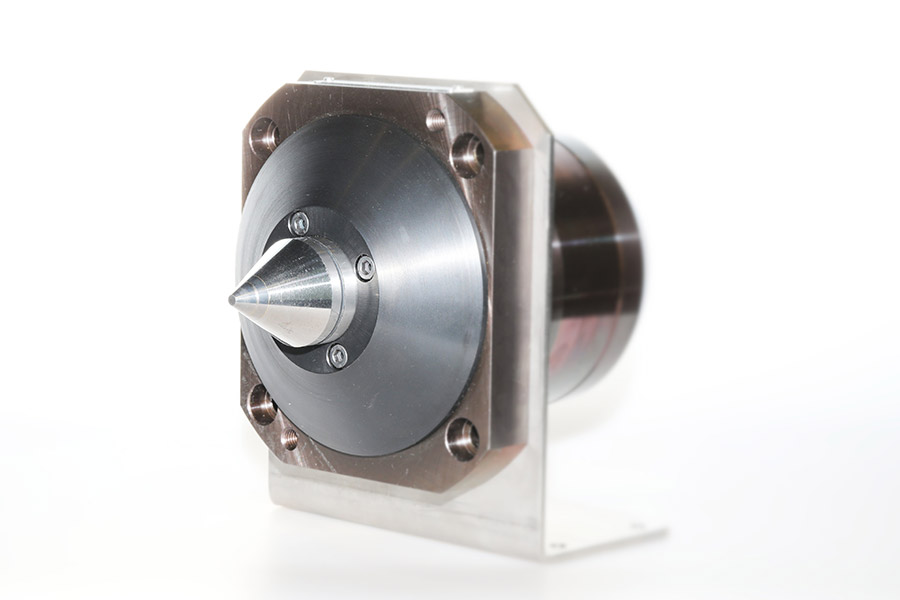

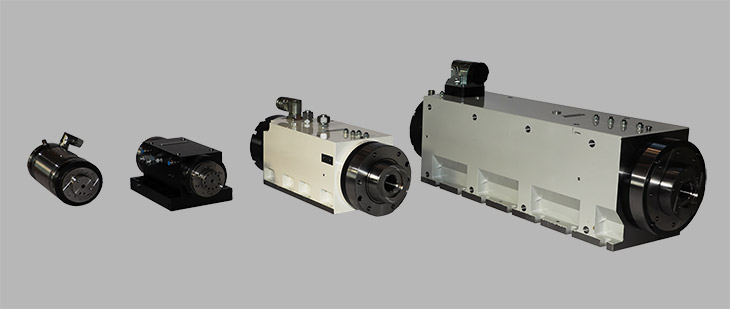

Special machine components developed by GST, both inside and outside the machine, facilitate work and secure the process. Because it’s the inner values that count, these core components are developed by GST and implemented in the machines.

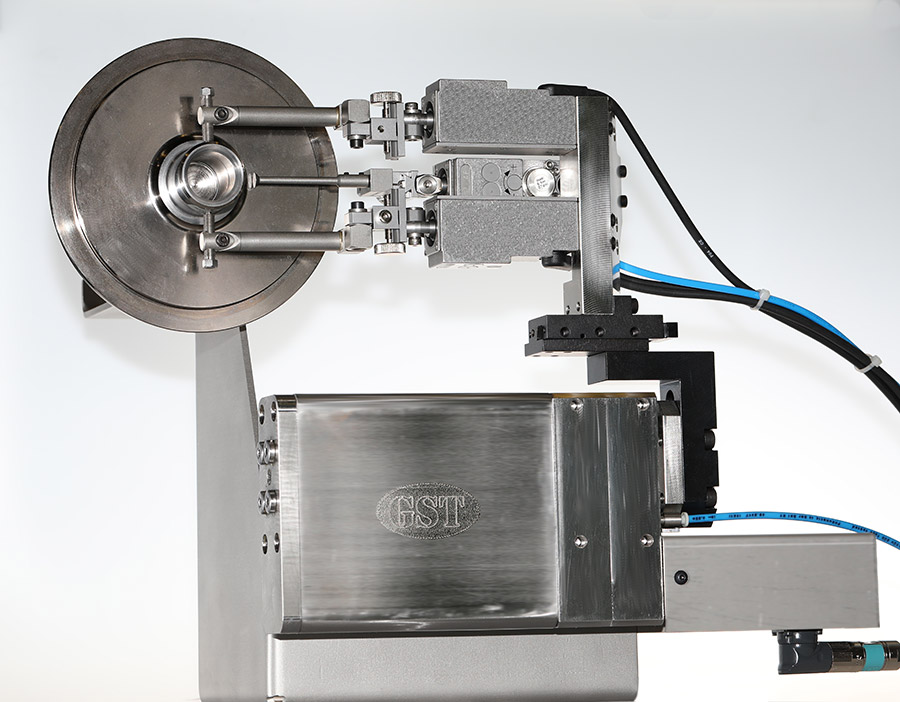

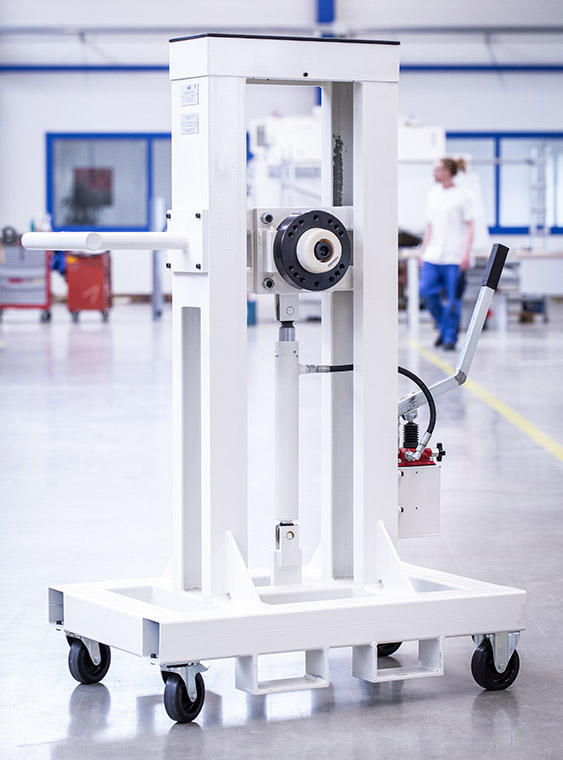

Grinding wheel trolley

Grinding wheel trolley