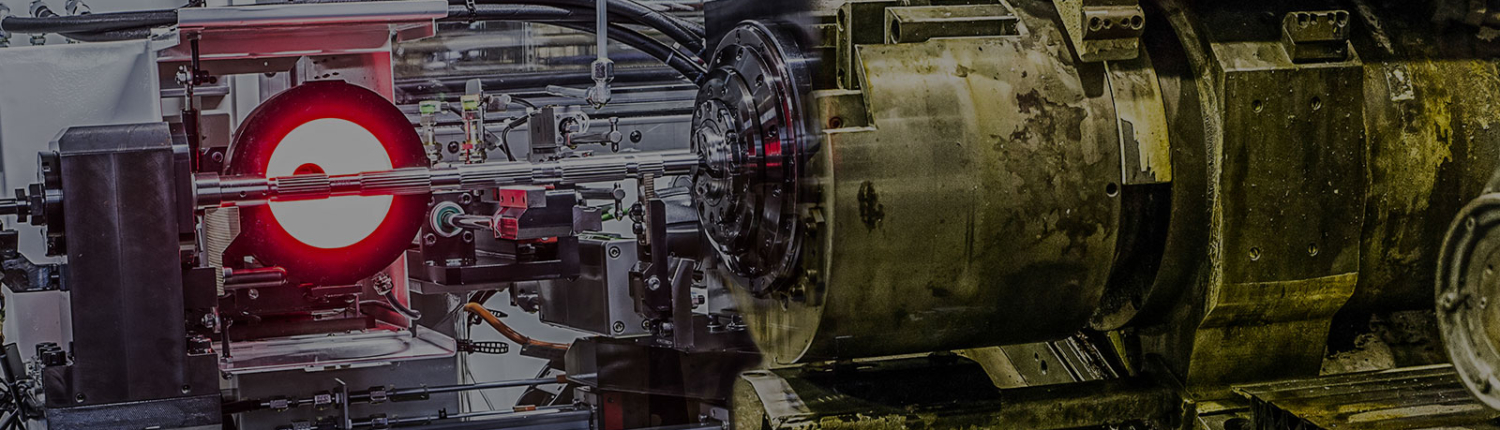

Old – New – Retrofit

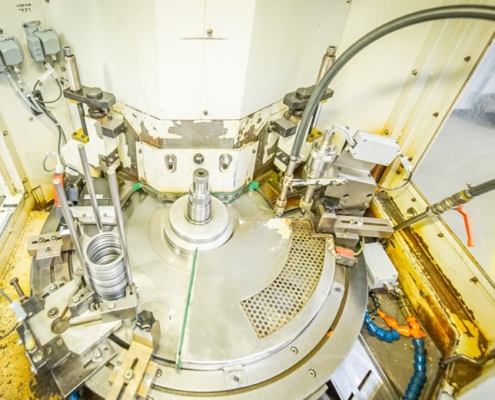

We will gladly help you to evaluate whether an overhaul or a new investment would be more economical. Upgrading is often the perfect solution. GST offer these services for their own machines as well as for machines from other manufacturers and any machine tools.

You just want to carry out selective renovations? No problem. We will implement your wishes.