Retrofit for Kehren grinding machines

You have come to the right place if you are looking for a retrofit for Kehren grinding machines. We offer the scope of services individually adapted to your needs. We are looking forward to your request!

Your benefits

- High cost savings compared to new investments ✓

- Increase the attractiveness of an existing machine ✓

- General overhaul in combination with retrofit possible ✓

- One contact person for scheduling and technical agendas ✓

- Technology optimization: new control technology, automation, etc.. ✓

- Fulfillment of the criteria according to safety technology ✓

- Customer employee trainings ✓

- Creation of new machine documentation ✓

- Warranty and spare parts guarantee ✓

Tailor-made solutions

Retrofit for Kehren grinding machines – tailored to YOUR needs! After the inital project kick-off at your plant, the mechanical, electrical and software related updates are planned and implemented at our site in Sierndorf. Our construction and production departments are located here – all in the same place – working closely together to fulfill all your demands.

Project details:

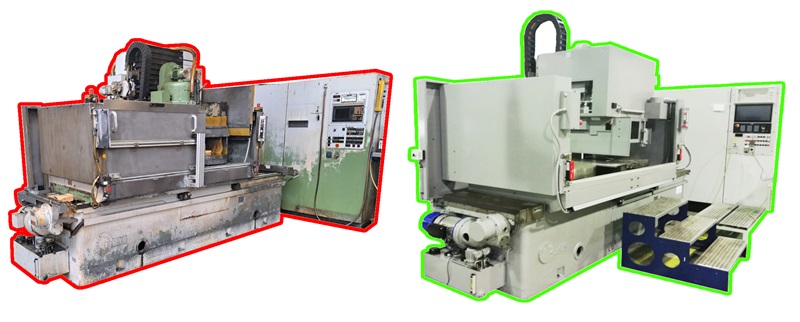

Retrofit surface grinding machine - brand Kehren (year of manufacture: 1992)

Our customer had been operating a Kehren surface grinding machine in his factory in Germany since 1992. After more than 30 years of use, a general overhaul was needed, which we were allowed to carry out in 2023/2024. The project was kicked off by an expert from our design department at the customer’s plant. Various possible options and scopes were evaluated and finally the following scope of services was agreed upon:

- Project scope:

- Schedule: 16 weeks at GST for the general overhaul

- Project support: A GST project manager is available for scheduling and technical topics during the entire duration of the project

- Pick up and drop off service: Disassembly and reassembly at the customer’s plant

- Mechanics & Fluid Technology:

- Dismantling, cleaning and replacing of all parts at the assembly level of the axes and grinding slides

- Overhaul of the machine guideways

- Replacement of the servomotors including supplementary mechanical construction due to the modified mounting

- Machine geometry including protocol

- New enclosed machine housing

- Renewal of the pipework for lubrication and coolant

- Control system:

- Renewal the old control system with a new Siemens Sinumerik ONE

- Electrical Technology:

- Renewal of the control cabinet and user interface

- Replacement of the drives

- New cables and wires

- New safety technology

- CE conformity declaration

- Modernized machine documentation

- Completion:

- Recommissioning

- Grinding tests/sample machining + machine capability test including statistical evaluation

- Staff trainings complete package

- 12 month warranty

Retrofit for Kehren grinding machines – made by GST – is a sustainable solution for the safe and worry-free use of your machine tools!

Feel free to contact us without any obligations!

Your contact person

Robert Promber, Ing.

Senior Technical Sales

GST Grinder GmbH

Your grinding machine manufacturer in Austria!

Contact me:

Phone: +43 (0) 2267 3250-32

Mobile: +43 (0) 650 3250 006

E-Mail: robert.promber@gst.at