Balance shaft grinding machine

You have come to the right place if you want to buy a new machine for grinding balance shafts. We manufacture your machine individually for your needs! We are also happy to build several balance shaft grinding machines of the same design for you. We look forward to your enquiry!

Your benefits

As a manufacturer of industrial grinding machines for metal, GST Grinder delivers highest precision solutions since 1992.

- Specialized in circular grinding ✓

- Completely individual ✓

- High-precision technology ✓

- Short retooling times ✓

- Integrated automation ✓

- Improved energy balance ✓

Tailor-made solutions

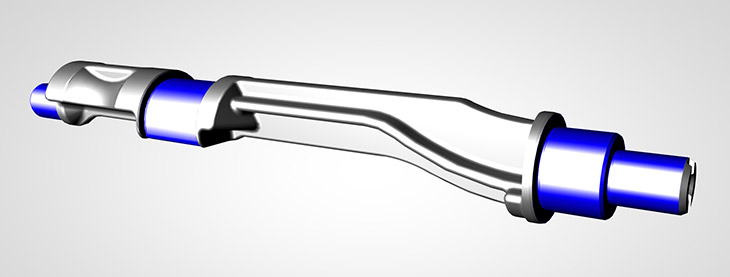

The balance shaft is an essential part of the internal combustion engine. When it comes to processing large quantities with highest accuracy, GST is a flexible provider for your requirements. Since the highest level of precision is required for this type of grinding, GST has developed various concepts. Depending on our customers’ requirements, each machine is specially planned, designed and manufactured in Austria according to highest quality standards.

Grinding diameters, flat surfaces & grooves

Examples of successfully realized projects:

Double Cycle Complete C/CBN - Double-spindle external cylindrical grinder for shaft production

Complete machining of the shaft in a single clamping setup. Double-spindle external cylindrical grinder with 2 work stations (2 slides on the Z-axis) for the grinding of diameters, plane surfaces and grooves in a single operation with 0 non-productive times.

- Cycle time 43“ = 0.72 min. = 1,600 parts/day with 80% capacity utilisation

- Non-productive times: 0 sec

- Axes with linear drive

- Machine designed for emulsion or oil

- Corundum or vitrified CBN grinding wheel for grinding diameters

- Electroplated CBN grinding wheel for grinding grooves and plane surfaces

- 1 work station, 2x Loading / unloading stations, identical operations

- Simultaneous loading & grinding

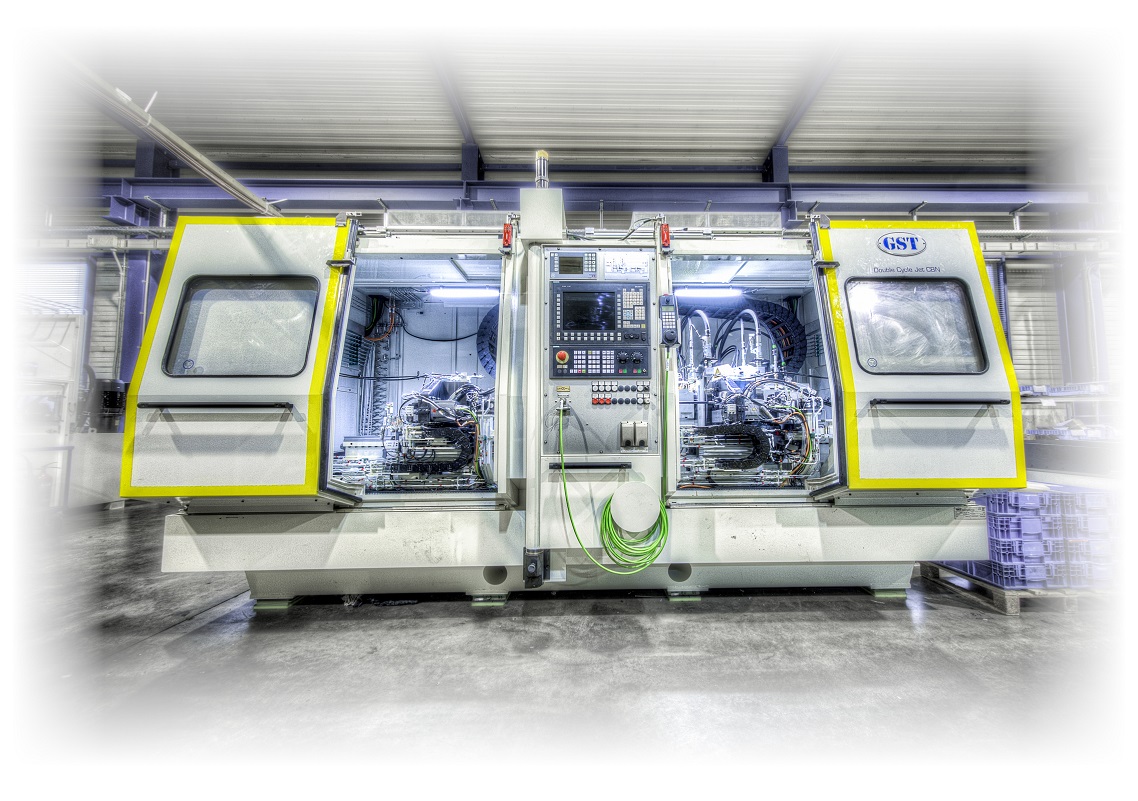

Double Cycle Jet CBN - Double-spindle external cylindrical grinder for shaft production

Complete machining of the shaft on 1 machine at 2 separate working stations. 2 slides on the Z-axis and 4 grinding wheels for simultaneous grinding of diameters, flat surfaces & grooves in 1 machine in 2 steps with 0 non-productive times.

- Cycle time 52“ = 0.87 min. = 1,318 parts/day with 80% capacity utilisation

- Non-productive times: 0 sec

- Axes with linear drives

- Machine designed for emulsion or oil

- Corundum wheel: for grinding diameters

- Electroplated CBN wheel: for grinding grooves and plane surfaces

- 2 different work stations

- Advancing by loader

Feel free to contact us without any obligations!

Your contact person

Robert Promber, Ing.

Senior Technical Sales

GST Grinder GmbH

Your grinding machine manufacturer in Austria!

Contact me:

Phone: +43 (0) 2267 3250-32

Mobile: +43 (0) 650 3250 006

E-Mail: robert.promber@gst.at