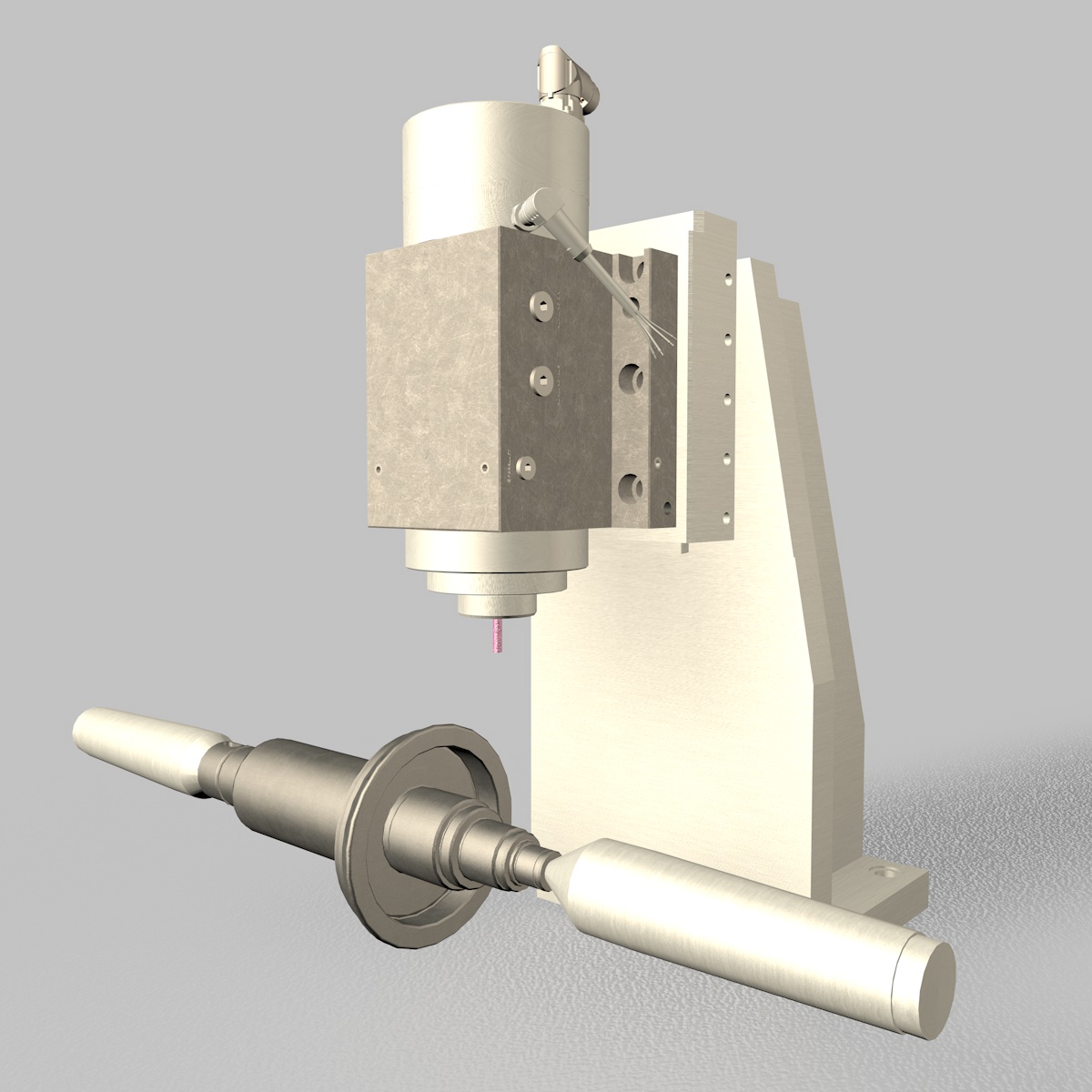

Grinding / Groove milling

In the GST machine, grinding is supplemented by the process of groove milling. As a result, you get a process-optimized special solution for your workpieces in just one machine. The GST turnkey system is designed for large-scale production.

Grinding / Groove milling

- Groove milling as a supplement to the grinding process in large-scale production.

- Using the stability of the grinding machine for the quality of groove milling.

- A method to completely process a workpiece with contours that are not grindable.

- Highest accuracy, as processing is made in just one clamping set-up.

- Control through the machine control system.

- Easy programming by parameterizing subprograms.

Your benefits

As a manufacturer since 1992, GST Grinder offers the highest precision in industrial grinding machines for metal.

- Specialized in cylindrical grinding ✓

- Entirely customized ✓

- High precision technology ✓

- Short changeover times ✓

- Integrated automation ✓

- Improved energy balance ✓

Customized solutions

When it comes to producing high quantities and achieving highest precision, GST is the flexible partner for your tasks. Since grinding operations require the highest accuracy, GST has developed several concepts. Depending on the customer’s requirements, our machines are specially designed, planned and manufactured in Austria according to the highest quality standards.

Feel free to contact us without any obligations!

Your contact person

Markus Aschauer, Dipl.W.Ing.(FH)

Technical Sales

GST Grinder GmbH

Your grinding machine manufacturer in Austria!

Contact me:

Phone: +43 (0) 2267 3250-24

Mobile: +43 (0) 650 3250 005

E-Mail: markus.aschauer@gst.at