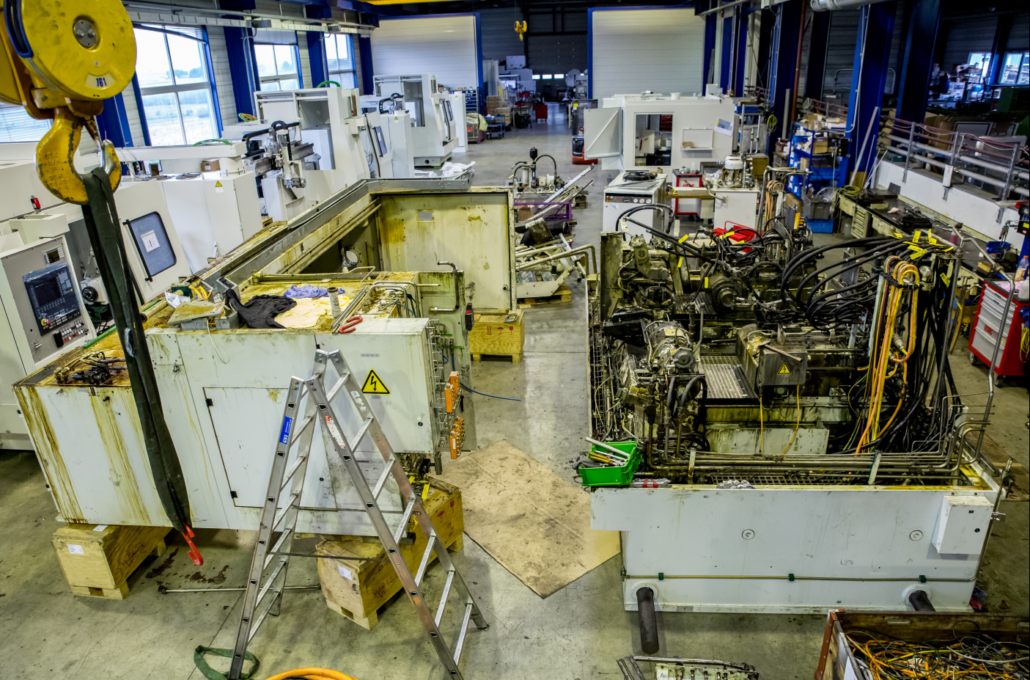

Grinding machine – Automation – Cleaning station – Coolant system – Post-processing station, all from a single source

Siemens could not have chosen a better name for their new control system. For GST Grinder Gmbh ‘One’ is the control system for the entire equipment. A wish that came from many machine operators has been fulfilled. Quite often countless industrial PCs are installed in one system. PCs of machine, automation, feed conveyor, cleaning station, post-process measuring station etc. are connected by different interfaces. In addition to the high costs of many systems, the frequency of malfunctions and their troubleshooting is also rather high. In most cases, a component control system contains much more information than is transmitted through an interface to the “head control – machine control system”. But software maintenance of control systems can also confront maintenance departments with unexpected problems. A post-process measuring station that works with a discontinued operating system and is upgraded on the software side only by replacing the hardware can be very time-consuming and cost-intensive. Automation systems with exotic controls or cleaning stations and coolant systems with small PLCs and hardware interface to the machine control system add to unnecessary complexity, since as well because here as well, any request for improvement or change always has to be made via two control units.

Needless redundancies are eliminated, the result is simplified – true to the principle: as much as necessary, as little as possible

This is why GST Grinder decided years ago to operate the entire system with one control. As a supplier of grinding solutions for large-scale production with very short cycle times and highest production quality, it is crucial to have all system information available. But even for our quick changeover machines, which cover complete part families, automated changeover is only possible with access to the complete system.

Step by step, in-house systems were developed to achieve this goal.

Machine-integrated automation for the quickest possible workpiece changeover allows shorter distances and optimised processes for each workpiece type and at the same time is much more cost-effective than external systems such as gantries or robots. The hardware and PLC programs for the control of external coolant systems and cleaning stations have been in use very successfully for many years and contribute to the understanding of the entire manufacturing process.

Research and development for a perfect grinding process:

As the latest product in this series, an optical post-process measuring station has been developed which is completely integrated into the machine control. There is no longer any need for costly mechanical changeover of the measuring station. All measurement data and information are stored in programmes. Only the cleaning of the workpieces must be ensured to enable the optical measurement. The demands on a PPMS are more than fulfilled. Programs for measuring equipment capability, machine correction, external data transfer and statistics are displayed on the machine control or, if required, on an additional monitor on the machine. But One not only applies to control technology. Mechanical assemblies that are responsible for the required manufacturing qualities are also GST’s own designs. Examples include:

Grinding spindles up to 100 kW with built-in motor, dressing spindles with one or two truing wheels, workpiece spindle systems with up to 4000 rpm or designed as C-axis, driving via centre points by the left and right workpiece spindle, workpiece clamping system by an NC-axis with variable clamping pressure adjustment – even during the process, electric measuring device slide, rotating centre point as tailstock insert, etc.

Leading through knowledge – the future of grinding is digital

One is the understanding of the collective whole, well-coordinated assemblies and processes that ensure quality and cycle time. Only those who know the options for intervention and the variants of the machine assemblies can always turn a wheel somewhere in order to improve quality or cycle time. Because there is no doubt that the future of grinding technology is also digital. Excellent knowledge of its assemblies and processes will make this major task easier. In doing so, GST Grinder GmbH clearly opposes the trend to install the cheapest possible assemblies from Asia or the East in their machines.

New brand “GST+” also a PLUS for other machine tools

On the contrary, with the GST+ brand, GST Grinder GmbH will offer assemblies and products that are especially suitable for retrofitting and upgrading grinding machines of any type. These products, specially developed for large-scale production and machines which can be quickly refitted, can be used in combination, but also “stand-alone”.Manufacturing quality can only be ensured through the precision of each individual assembly. From start to finish.